Monthly Archives: February 2014

february process

In the months since visiting New York, other than working on my written element deadlines, the introduction, outline and bibliography for my manual on wire walking, I have been planning a project which in many ways represents an apex of the work that I have developed since entering Transart. I want to challenge my wire skills with an ambitious and spectacular project.

I have been dreaming of walking a real sky wire, a wire which is high in the air and spans a long distance, ever since beginning my practice of funambulism. I believe that I may be ready for such a wire and have begun to prepare and gather the equipment for this project. I have selected the same gorge which I walked across last year, but this time I plan to set my wire across the widest and deepest portion.

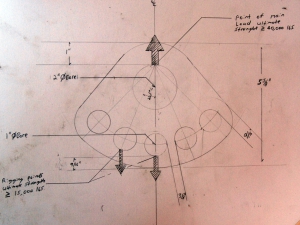

After doing some triangulation calculations with a compass and tape measure, I and my friend Chuck ,determined that the distance between anchors is about 300 feet. This is four times longer than any high wire I have walked! At it highest the wire will be over 300 feet high. I have selected the location of one anchor, but still have to do some more exploration for the other. On the west end I will place 3 or 4 glue-in bolts in a compact and solid flow of basalt.

Unfortunately on the east side, the structure of the rocks is less apparent and I am still a little unclear of how exactly I am going to build this anchor. Tomorrow I head up there to examine it more closely. I may decide to drive stakes into crack between basalt columns or perhaps place bolts into the top of rock columns. However the topography of the rocks makes it hard to determine the integrity of the individual columns. I think when the anchor is constructed I will have to test the individual placements to be certain that they are capable of supporting the tension of the wire.

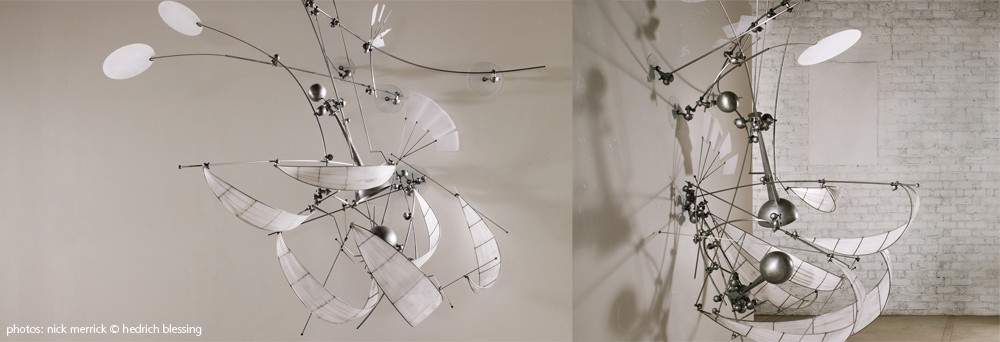

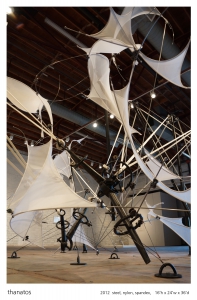

For the bolt anchors I have repurposed some anchors plates which I made for a 2012 large sculptural installation of mine called Thanatos.

However the installation’s webbing was not near the tensions which these anchors will be subjected to, so I have proof tested the anchors plates to be sure they are strong enough.

I bolted two of them together and was able to proof them to 10,000 lbs at which point the plate around the bolt which connected them together began to yield. One can tell it has begun to yield because the mill scale — a layer of oxide which is formed in the manufacturing of the hot rolled steel plate — has fractured. The mill scale is brittle, unlike the ductile steel it covers, so its fracturing can be used as an indicator that the steel has changed form permanently. Or in engineering language, the steel has yielded.

The good thing is that each plate responded to the proof load in the same way. The welds and the semi circular rod showed no signs of deformation. I think ultimately these would fail by the plate bending into a taco form, putting tremendous strain on the inner section of the rod weld. The steel around this weld would crack and one side would rip free. I am not sure of how much tension would be required for catastrophic failure, but judging from the proof tests, it is much more than the high wire will be subjected to. Individually the plates will be subjected to around 2000 lbs, so they have been proofed to 5 times this load which creates an excellent safety margin.

Other details of planning have included determining the adhesive and embedding depth of threaded rods to which the plates are bolted. I have selected a high strength structural threaded rod (ASTM A193 Grade B7) and matching structural nuts for connecting the plates to the rock. I am using a high strength Simpson AT, a two part acrylic adhesive, which when properly installed will develop a bond strength stronger than the steel or rock. I am hoping to place the bolts within the next week. It would be good to allow them time to fully cure as it is winter and the temperature of the rock is cold, making the adhesive cure more slowly.

I am excited about this high wire. It is definitely a big step up from anything which I have yet done. It is a serious rigging and performance undertaking, presenting new challenges and problems from which I am eager to learn. But beyond the technical preparations, engineering, and installation, there are unknowns which I will not able to answer with planning. What is it going to be like performing on a wire which crosses such a great volume of space for me to find balance when I am so far from the ground and ends? I know balancing is harder when I am extremely isolated in space and far from solid ground. I can only imagine that it is going to be quite different from the high wire of which I am accustomed, one that is only 40 feet long and 33 feet high. My second concern related to the first is what sort of dynamics and behavior is such a wire going to have? As I walk and balance on it I feel that I am going to introduce side to side and up and down motions which can build into waves, creating oscillations which ripple from end to end, making balancing upon the wire all but impossible. I am going to place two stabilizing guy lines 100’ feet in from each anchor point. These stabilizers help dissipate the oscillations. Even with the stabilizers the wire is going to be swaying and rolling about. Whether I have the skill to remain in balance in the midst of vacuous space on a dancing wire remains to be seen. I have never seen a picture of a wire walker on such a long and high span without a pole. It will be interesting to see if it is possible to walk such a wire without a pole. I am certainly going to use a safety tether for safety. Hopefully by next month I will have accomplished this walk and have some good documentation to show of it. Hope everyones’ projects are fruitful.

best jamie